Investment casting

Investment casting: an ancient technique

The investment casting process was born in ancient times and was used by populations and cultures spread throughout the earth, from the Egyptians to the Aztecs, from the Greeks to the Romans, in order to produce everyday tools and sculptural works. This process was used to create monumental statues, including the very famous Riace Bronzes, dating back to 500 BC. approximately, the imposing Winged Victory, a two meter high bronze statue dating back to the first century AD, the marvelous Perseus by Benvenuto Cellini created in the Renaissance era.

Investment casting is still used by important sculptors in the modern era as well, but has also found wide application in many areas of the the industrial production, especially starting from the beginning of the 1940s in the USA and subsequently all over Europe, with a constant success.

Investment casting is still used by important sculptors in the modern era as well, but has also found wide application in many areas of the the industrial production, especially starting from the beginning of the 1940s in the USA and subsequently all over Europe, with a constant success.

The benefits of microcasting

Investment casting is the optimal solution to realize "all in one" parts that are normally carried out trough different production steps and assembly processes (ex: welding process). Several production phases are eventually reduced and difficult assembly operations, as well as costs, are avoided.

Furthermore investment casting process allows a great flexibility on the choice of the alloy, including special materials that on one hand improve the quality of the parts but on the other are hardly machined or even impossible: lost wax casting it's fundamental on the processing of many special alloys like stainless steels, carbon steels (low and high alloyed), cobalt and nickel based steels.

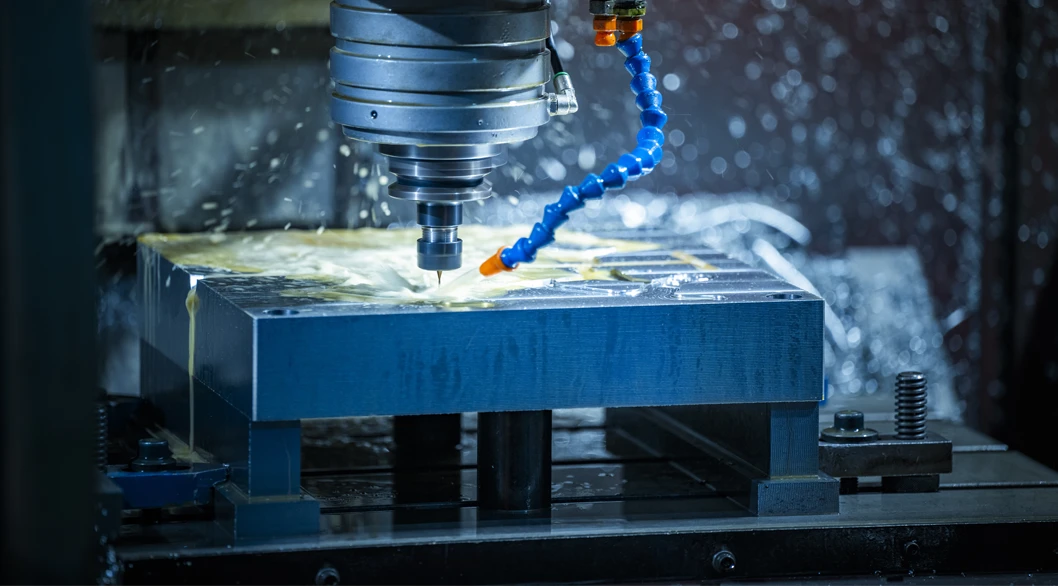

The possibility to realize extremely complex geometrical shapes makes of this process the most indicated when particular characteristics, not feasible by other processes, as connections, intersections, stiffening ribs and grooves, are required.

High surface finishing (between 1,6 to 3,2 Ra) is combined with dimensional accuracy (±0,7% of the nominal dimension) and most of the times allows the production of ready finished parts, without the need of further operations.

The beginning of the production process

The beginning of the production process

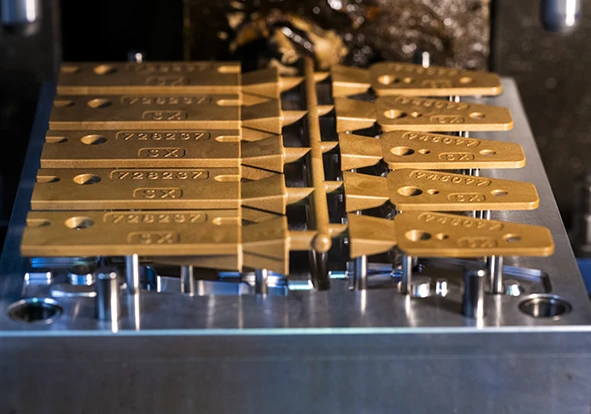

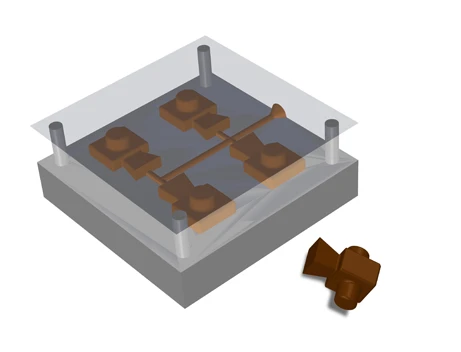

Mould creation is the very first step in order to produce the requested object; this can be obtained by choosing between two different techniques:

- a soft tool made by resin materials (very useful for low volumes and for prototyping);

- a metal tool made by steel or alluminium, with different items or multiple cavities.

Process steps

1

Mould creation and subsequent production of wax patterns trought an injection machine.

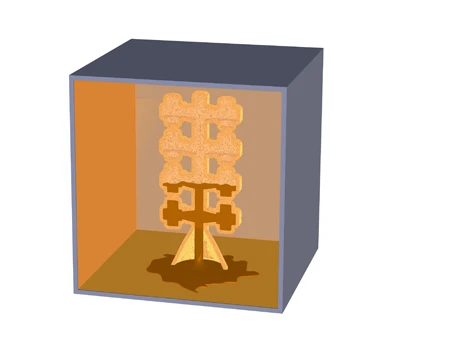

2

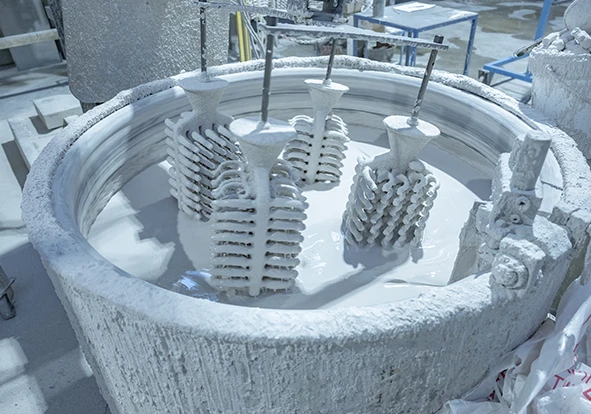

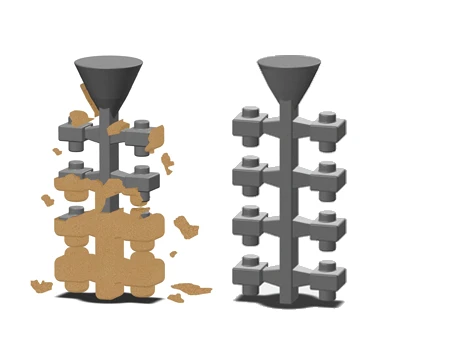

Cluster assembly, by sticking wax patterns on a wax tree.

3

Cluster dip into a ceramic binder.

4

Rainfall sanding of the cluster with refractory granules.

5

Wax outflow trought an autoclave.

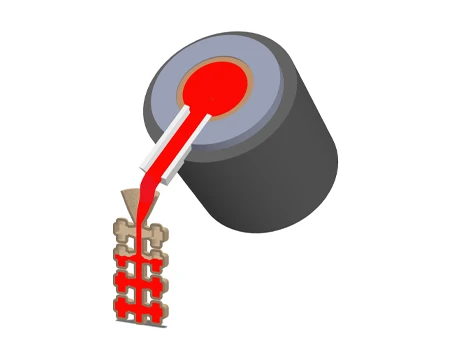

6

Molten steel poured into the heated ceramic cluster.

7

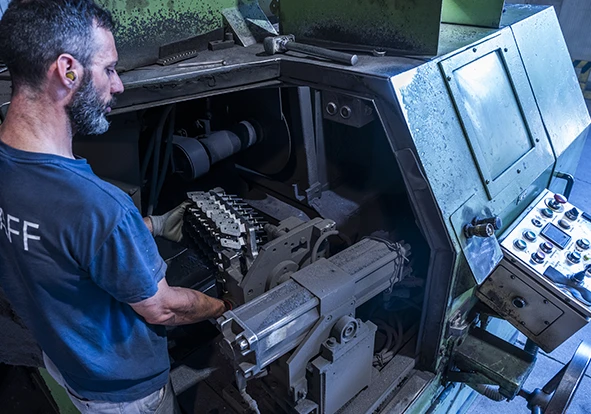

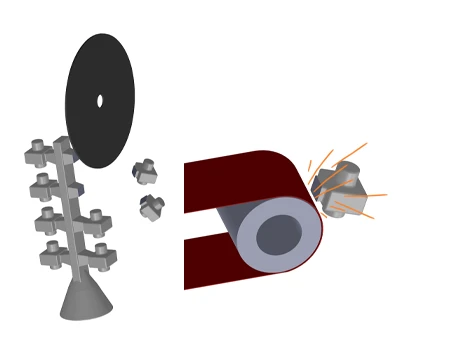

Ceramic lining knock out.

8

Parts separation from the cluster and subsequent finishing.